Category of a waste wood boiler

There are many different regulations around the types of waste biomass that can be burn in a boiler. Whichever waste that needs to be utilised, will determine the emission regulations that the environment agency set out for the given type of fuel, and therefore determine the type of boiler and equipment that will be required. The volume of fuel through put will also have a bearing on whether this will fall under the Environment agency or the local authority.

Fuel

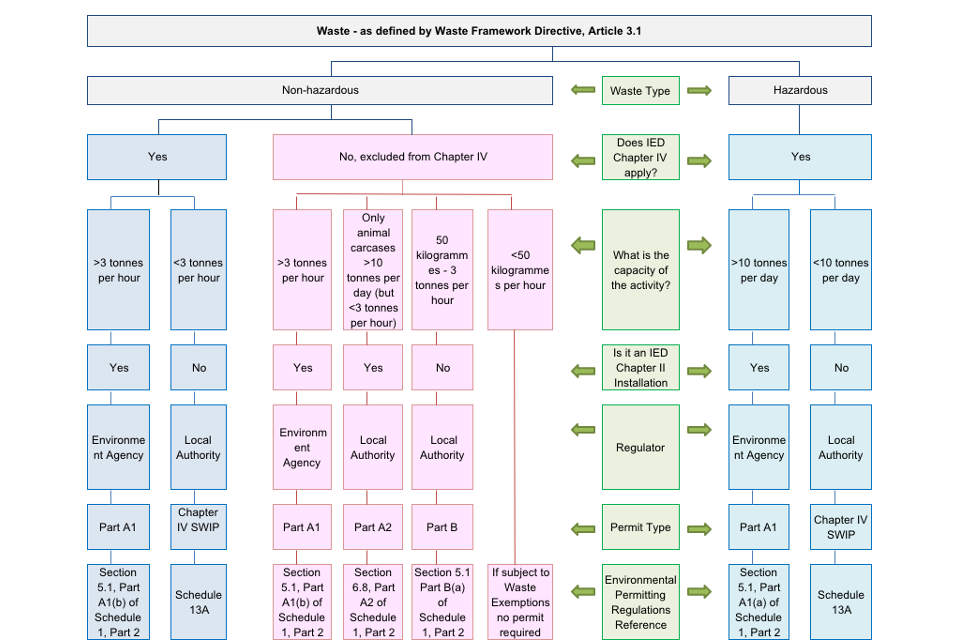

The first thing to consider before anything else, is to categorise the type of waste that you have, this will then determine the regulations. For example, Horse waste will come under the WID / IED regulations, whereas waste pallet wood produced as a by-product of the manufacturing process will be classed as A/B grade wood waste and can then be burnt in a standard boiler under a simple U4 exemption from the Environment agency or under a part B permit. At the bottom of this document is the government guidance on how to define the waste. I would however recommend contacting an expert in the field to help you to define your specific waste.

Boiler specifics, Equipment and costs

Once the fuel has been categorised the boiler and equipment can be specified for the requirements needed for any given site.

Below is a list of items that can form part of a biomass system. These items can vary by a huge amount depending on the type of boiler required, for example a standard boiler burning “A” grade wood waste would not require any flue monitoring equipment, whereas a boiler under a part B permit may require £30,000 pounds worth of monitoring equipment and a boiler that is WID/IED compliant may require £130,000 Pounds worth of constant flue monitoring equipment. It is therefore very important to correctly define your waste!!!

It is also very important to source a boiler that has been installed in the UK under the regulations that you need to comply to. This is because many companies claim to comply with this however there are many regulations that the boiler manufacturers need to comply with. For example under the WID / IED regulations the boiler must have a combustion chamber that holds the gasses inside the boiler for a minimum of 2 seconds, it must also have a fossil fuel burner to pre-heat the combustion chamber as the regulations state that the waste cannot enter the boiler until the chamber has reached 8500c, it must also do this in reverse when the waste is stooped being fed into the boiler.

The boiler will need to reach 11000c in the post furnace if you have more than 1% of halogenated organic substances, expressed as chlorine. It may also need lime injection or a catalyst to ensure that the emissions fall within the parameters set out in the permit required.

- Boiler (fossil fuel burner)

- Filter (ceramic, bag, multicyclone)

- Fuel store (agitator, walking floor)

- Feed system (augur, conveyor, push ram)

- Flue (CEM’s, Constant monitoring)

- Shredding equipment

- Drying floor/conveyor

- Hydraulic equipment (pumps, pipe, expansion, insulation etc)

- Controls interface

Selected Eco Energy have been in the waste to energy market for the last 10 years and have many installations that conform to differing standards for the Environment agency. Please feel free to contact us at info@www.mechselectedservices.co.uk or call 07929206094 for further details.

do you manufacture 3mw biomass with ocr. if so what is lead time from order placement.

regards

You will be typically looking at a 12 week lead time on a boiler of this size. With an ORC taking around 8 weeks depending on the size.